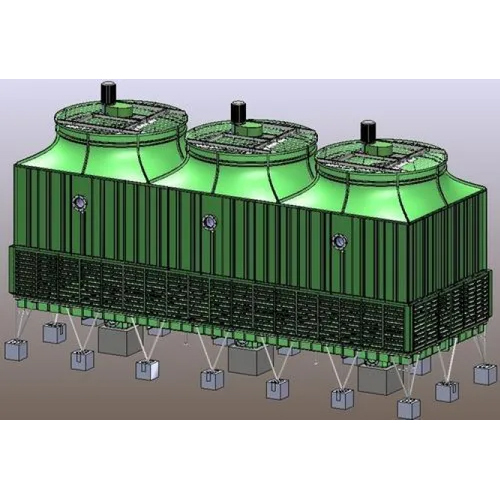

Fanless Cooling Towers

Product Details:

- Motor Not Required (Fanless Design)

- Material FRP

- Application Industrial Water Cooling

- Refrigerating Capacity Up to 1000 TR (Tons of Refrigeration), Model Specific

- Usage Industrial

- Condition New

- Dimension (L*W*H) Custom Sizes Available (Model Dependent), Typical: 2.5m x 2.5m x 4.5m

- Click to View more

X

Fanless Cooling Towers Product Specifications

- Low Noise (Silent Operation, No Fan)

- Industrial

- Blue

- Fanless Cooling Towers

- 10 - 200 m/hr (Model Dependent)

- New

- Up to 1000 TR (Tons of Refrigeration), Model Specific

- PVC / Polypropylene

- Not Required (Fanless Design)

- FRP

- Industrial Water Cooling

- Not Required for Fanless Operation

- Custom Sizes Available (Model Dependent), Typical: 2.5m x 2.5m x 4.5m

- High (FRP Casing)

- Low, No Fan or Gearbox

- Access Hatch, Water Level Indicator, Distribution Pipes Included

- Honeycomb PVC Film/ Splash Bar Option

- Outdoor, Easy Foundation

- Cylindrical/Bottle Shape for High Thermal Performance

- 10 TR 1000 TR

- Flanged/Threaded as per Order

- Non-clogging Fixed / Rotating Sprinkler

- Eco-friendly, Minimal Water & Power Consumption

- Energy Saving, No Power for Air Movement

- <0.1% of Circulating Water

- Up to 50C

- Optimized with Large Wetted Surface

- Designed for 15+ Years of Service

Product Description

Mark down operating costs and redeem substantial energy savings with Avirats laureate Fanless Cooling Towers, engineered for industrial excellence. With a remarkable capacity range of 101000 TR and bottle/rectangular shape options, these towers offer terrific thermal performance and an eco-friendly footprint. Their high FRP corrosion resistance and innovative honeycomb PVC fill assure minimal drift loss (<0.1%%), while non-clogging sprinklers optimize water distribution. Enjoy the best silent operation, as no fan or motor is requiredmaking maintenance effortless while extending service life up to 15+ years.

Unmatched Industrial Cooling Solution

Fanless Cooling Towers are ideal for diverse plant applications, perfect for the plastic, pharma, chemical, aluminum casting, and PET bottle packaging sectors. The main advantage lies in their rugged FRP build and energy-saving fanless design. Used for efficient, silent outdoor cooling and high-volume refrigerating (up to 1000 TR), their minimal drift loss and low-maintenance requirements make them invaluable for process industries seeking cost-effective, high thermal performance.

Efficient Delivery, Secure Exchange, and Wide Reach

Delivery time for Fanless Cooling Towers is prompt and reliable, supporting both domestic markets and international exports. Payment terms are flexible, adapted for seamless business exchange, and packaging is robust to ensure safe transport. Avirats main export markets include Asia and Europe, with domestic mar demand rising steadily. Each unit is custom-packed according to model specifications, guaranteeing safe arrival and product integrity.

Unmatched Industrial Cooling Solution

Fanless Cooling Towers are ideal for diverse plant applications, perfect for the plastic, pharma, chemical, aluminum casting, and PET bottle packaging sectors. The main advantage lies in their rugged FRP build and energy-saving fanless design. Used for efficient, silent outdoor cooling and high-volume refrigerating (up to 1000 TR), their minimal drift loss and low-maintenance requirements make them invaluable for process industries seeking cost-effective, high thermal performance.

Efficient Delivery, Secure Exchange, and Wide Reach

Delivery time for Fanless Cooling Towers is prompt and reliable, supporting both domestic markets and international exports. Payment terms are flexible, adapted for seamless business exchange, and packaging is robust to ensure safe transport. Avirats main export markets include Asia and Europe, with domestic mar demand rising steadily. Each unit is custom-packed according to model specifications, guaranteeing safe arrival and product integrity.

| Usage/Application | Plastic, Pharma, Power, Chemical, Color, Aluminum Casting, PET Bottles Packaging Industry, etc |

| Brand | Avirat |

| Capacity | 5-500 TR |

| Shape | Rectangular |

| Tower Material | Fiberglass Reinforced Polyester |

| Tower Type | Forced Draft |

| Tower Design | Counter Flow |

| Color | Blue |

| Inlet Temperature | 60 Deg C |

| Cooling Speed | 50-3000 l/min |

FAQs of Fanless Cooling Towers:

Q: How does the fanless design benefit industrial cooling applications?

A: The absence of a fan means no power is needed for air movement, drastically reducing both energy and maintenance costs. This leads to reliable, silent operation and extended product lifespan.Q: What is the process for installing a Fanless Cooling Tower?

A: Installation is simplified due to easy foundation requirements and the lightweight FRP casing. Units are outdoor-ready, and connection ports are provided flanged or threaded as per order specifications.Q: Where can Fanless Cooling Towers be used most effectively?

A: These towers are best suited for industries such as plastics, pharma, chemicals, aluminum casting, and PET packaging. They are optimized for high ambient temperature operations up to 50C.Q: When should I consider switching to a fanless cooling system?

A: Switch to fanless cooling systems when seeking significant energy savings, minimal water loss, low maintenance, and when noise control is a priority in your plant operations.Q: What advantages do honeycomb PVC fill and FRP casing provide?

A: Honeycomb PVC fill ensures large wetted surfaces for superior thermal efficiency, while robust FRP casing provides high corrosion resistance and lasting durability, keeping maintenance low.Q: How does water distribution remain efficient in these towers?

A: The towers feature a non-clogging fixed or rotating sprinkler system, distributing water evenly across fills for optimal cooling and reduced drift loss (<0.1%% of circulating water).Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email