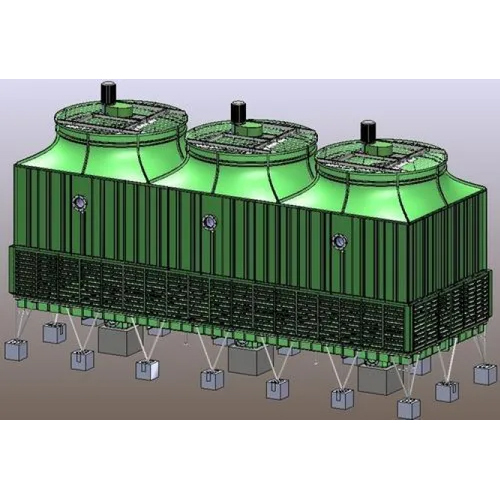

Forced Draft Cooling Tower

Product Details:

- Air Flow 8500 CFM

- Material Fiber Glass

- Refrigerating Capacity 100 TR

- Application Industrial

- Motor 5 HP

- Usage Industrial

- Condition New

- Click to View more

X

Forced Draft Cooling Tower Product Specifications

- 100 TR

- Low Noise Design

- 60 m/hr

- New

- Industrial

- GI (Galvanized Iron)

- Fiber Glass

- 8500 CFM

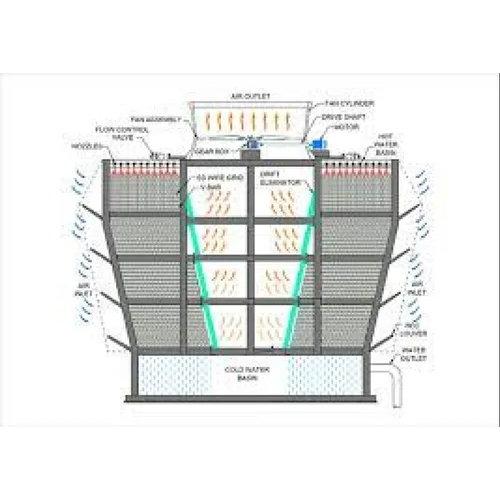

- Cross Flow

- Cooling Tower

- Forced Draft

- 415 V

- 5 HP

- Industrial

- 3 Phase, 50 Hz

- Blue

- 1850 mm x 1850 mm x 2100 mm

- 3 HP

- PVC

- PVC Honeycomb

- Aluminum

- 15 Years

- Outdoor

- Hot Dip Galvanized Steel

- 900 mm

- 60°C

- Less than 0.02% of Circulating Water

- 100 mm

- 1440 RPM

Product Description

Experience unrivaled cooling efficiency with our Forced Draft Cooling Tower, championed by its enlightened design and durable construction. Procure this industrial marvel featuring a fan diameter of 900 mm, aluminum blades, and a frame crafted from hot dip galvanized steel. Ensure instant checkout and markdown pricing for distributors, manufacturers, and suppliers across India. With less than 0.02%% drift loss, advanced PVC honeycomb media, and a service life of 15 years, this blue fiberglass tower is engineered to excel under demanding industrial applications. Low noise and powerful 5 HP motor guarantee optimal performance.

Application Scope & Usage Excellence

The Forced Draft Cooling Tower is expertly designed for industrial use, particularly in facilities demanding robust refrigerating capacity and high water flow rates. Its round shape, durable fiberglass construction, and counter flow design make it suitable for various sectors including manufacturing, chemical processing, and power generation. Benefiting from cross-flow and counter-flow cooling, this tower enhances operational reliability and maximizes equipment longevity in challenging environments where continuous cooling is indispensable.

Sample Policy & Packaging Details

Our sample policy supports seamless handover and exchange of sample units at genuine market value. Samples are available for qualified industrial clients, allowing thorough evaluation before full procurement. The cooling tower is packaged securely with industry-standard materials to ensure integrity during transit. Our commitment to transparent exchange and reliable sample offerings assures clients of product quality and operational suitability prior to large-scale installations.

Application Scope & Usage Excellence

The Forced Draft Cooling Tower is expertly designed for industrial use, particularly in facilities demanding robust refrigerating capacity and high water flow rates. Its round shape, durable fiberglass construction, and counter flow design make it suitable for various sectors including manufacturing, chemical processing, and power generation. Benefiting from cross-flow and counter-flow cooling, this tower enhances operational reliability and maximizes equipment longevity in challenging environments where continuous cooling is indispensable.

Sample Policy & Packaging Details

Our sample policy supports seamless handover and exchange of sample units at genuine market value. Samples are available for qualified industrial clients, allowing thorough evaluation before full procurement. The cooling tower is packaged securely with industry-standard materials to ensure integrity during transit. Our commitment to transparent exchange and reliable sample offerings assures clients of product quality and operational suitability prior to large-scale installations.

| Tower Type | Induced Draft |

| Cooling Capacity | 80 TR |

| Capacity | 80 TR |

| Usage/Application | Industrial |

| Shape | Round |

| Tower Material | Fiberglass Reinforced Polyester |

| Supply Phase | Three Phase |

| Tower Design | Counter Flow |

| Country of Origin | Made in India |

FAQs of Forced Draft Cooling Tower:

Q: How does the Forced Draft Cooling Tower maintain low drift loss?

A: The cooling tower is engineered with advanced PVC honeycomb filling media and precise fan control, limiting drift loss to less than 0.02%% of circulating water, thereby conserving water and improving overall efficiency.Q: What is the recommended area of application for this cooling tower?

A: This tower is ideally used in industrial applications such as manufacturing plants, chemical facilities, and power generation units where efficient and continuous cooling is required.Q: When can samples of the cooling tower be handed over for evaluation?

A: Samples are available by request to qualifying industrial clients. The handover process is streamlined, ensuring samples are exchanged at market value and delivered promptly for assessment before bulk procurement.Q: Where is this product manufactured and supplied?

A: The Forced Draft Cooling Tower is manufactured in India and supplied nationwide through authorized distributors, manufacturers, and suppliers, ensuring reliable support across diverse industrial sectors.Q: What benefit does the fiberglass material provide in tower construction?

A: Fiberglass reinforced polyester offers high strength, corrosion resistance, and a longer service life, making the tower suitable for challenging outdoor conditions and extending its operational lifespan up to 15 years.Q: How does the low noise design benefit industrial usage?

A: The low noise design of the cooling tower ensures minimal disruption in industrial environments, promoting workplace comfort and compliance with noise regulations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email